Our vision for the future of recycling

THE RECYCLED RAW MATERIALS OF TOMORROW

Recycled raw materials will be dominant in our industries by the end of the 21st century. France is a technological leader in recycling thanks to the excellence of this industrial sector.

The environmental benefits of this industry are well-known; it enables local production of raw materials. It also contributes to energy autonomy, by producing fuel or energy. To meet the challenges of quality and volume, processing technologies are becoming increasingly sophisticated: automated sorting, material recognition, material refining, etc...

Regulatory changes, legal harmonisation, consultation of stakeholders, and collaborations help to create economically viable conditions to enable the creation of organised industrial sectors and the deployment of ambitious industrial strategies for these businesses of the future.

And in 2030, what will the future hold for each major waste category? How can we improve their recovery? Here is a little exercise.

PLASTICS

Today, almost all kinds of plastic materials can be recycled.

In ten years’ time, recycling will enable the sorting and recovery of mixed plastics at end of life or originating from electronic waste. The range of recycled plastics will include noble products: polyamide, polycarbonate, PMMA, etc.

Plastics engineers will learn to use both virgin and recycled materials. They will be required to include a large proportion of recycled materials in any packaging provided to consumers.

IRON

Iron is already one of the world’s most recycled materials. On average, the recycling industry supplies approximately 30% of global requirements for the production of steel.

In ten years’ time, various stakeholders will have joined forces and the sector will become more professionalised. Participants will specialise in market segments.

The profession will also move towards the exploitation of new sources: planes, ships, and buses that are no longer in use, etc. The new EPR will transform the sector.

NON-FERROUS METALS

Aluminium, copper, lead, zinc... Recycled non-ferrous metals are also reused in production. More than 30% of the aluminium produced worldwide is made from recycled materials. This material is infinitely recyclable!

The proportion of recycled material in production applications has increased to 40% for copper. And these figures continue to rise significantly.

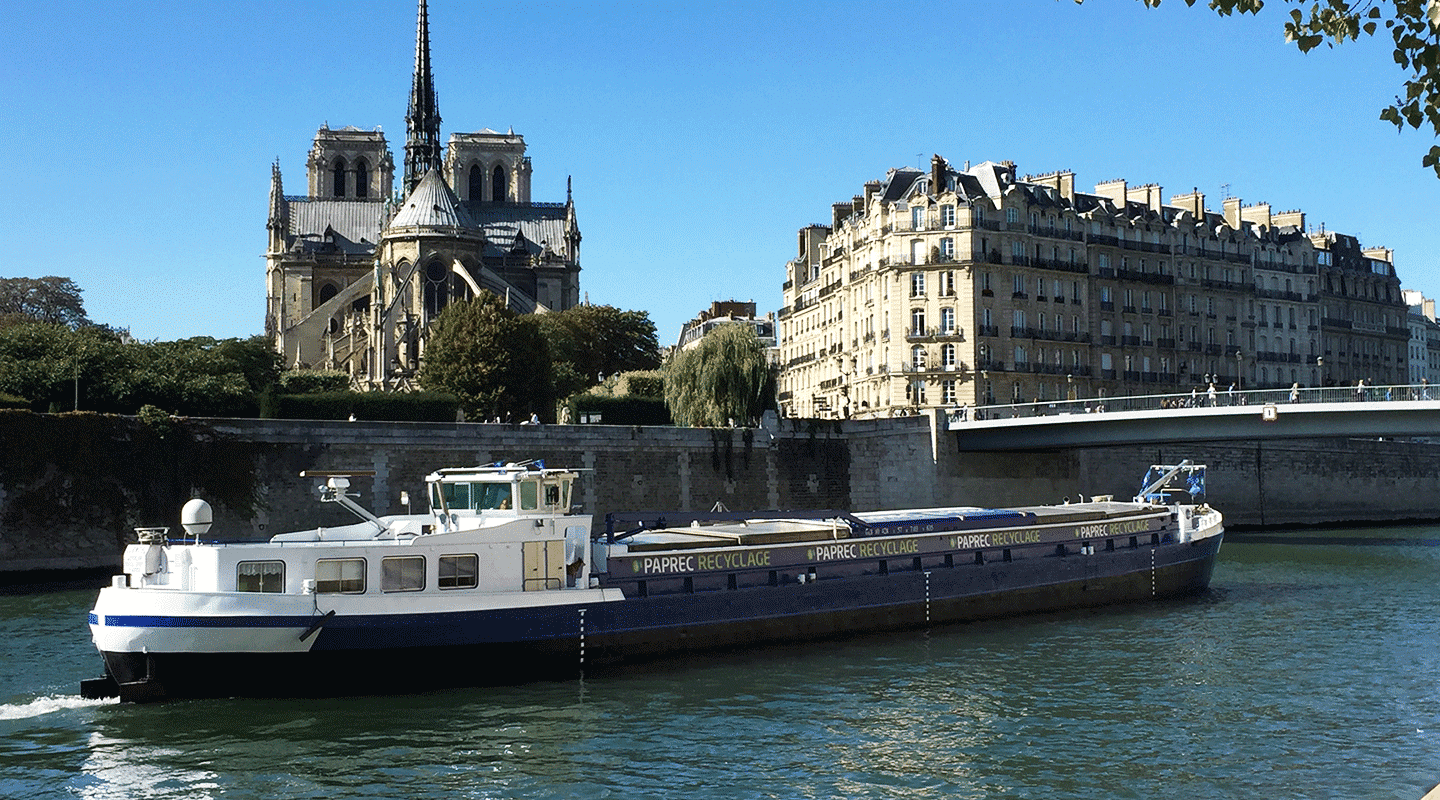

PAPER - CARDBOARD

Recycled paper fibre sources already represent more than 50% of the world’s paper industry supplies and more than 80% of paper manufacture in France.

Optimised sorting centres will be processing increasingly large volumes and separating different sources of paper automatically.

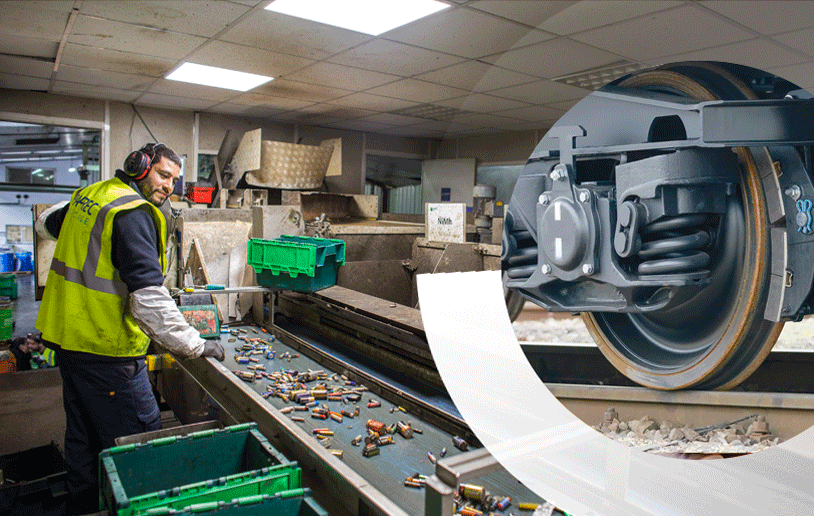

BATTERIES

34% of used batteries and accumulators are collected today. In ten years’ time, recycling will make batteries a significant source of iron and zinc.

The lithium from accumulators will be reused in batteries for electric or hybrid cars.

ELECTRICAL AND ELECTRONIC EQUIPMENT

Electronic waste (WEEE) is already collected and processed today. In ten years, the volumes processed will be much higher.

The sectors have become more specialised and waste treatment sites have been industrialised. Transparency for customers and safety for operators will prevail.

FOOD WASTE

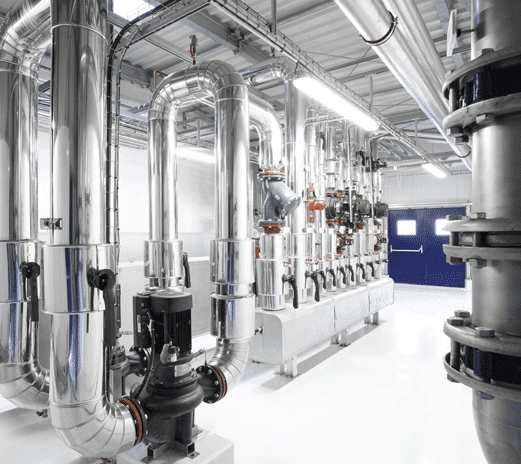

Food waste treatment has mainly developed around the agri-food industries, major manufacturers and a few pioneering local authorities. In ten years’ time, sorting biowaste at source will be self-evident and our children will be astonished to know that this was not always the case.

Composting and methanation streams will develop to fulfil the needs for producing high quality local fertiliser to rise to economic and climatic challenges and to keep up with regulatory developments. New local collection schemes will be developed, and will comply with strict health and safety requirements.

Composting and methanation units will enable our food waste to complete the loop, being returned to the fields in the form of compost and digestate to help produce new food.

WOOD

In ten years’ time, all wood sources, including green waste and forest waste, will be exploited.

Wood energy will make a significant contribution to the national energy bouquet thanks to incineration-cogeneration.

SOLID RECOVERED FULES

80% of post-sorting waste is not recovered today. Ten years from now, the production of solid recovered fuel will exploit this final source.

Thanks to changing usages, it will replace a large proportion of traditional fuels.

ENGINEERED LANDFILL

Today, storing non-hazardous waste remains the only solution for managing certain types of waste; it is a common solution, particularly in areas where installing an incinerator is not viable. Waste storage is an activity that has changed significantly since France closed its “municipal tips”, which have been replaced by modern storage sites for non-hazardous waste. The sector must comply with increasingly strict regulatory requirements to ensure the protection of people and the environment.

The sites are equipped to recover the energy produced in the form of biogas, which is used as a heat source, or turned into natural gas or electricity. These facilities also contribute to the production of alternative energy from waste, and contribute to the overall energy mix.

In ten years’ time, thanks to the development of energy recovery and recycling, the volume of waste in landfills will be in constant decline. Performance requirements will be increased, with restrictions on acceptable materials and an obligation to produce energy.

Furthermore, “mining” operations on old sites will enable the recovery of final waste for which new energy or material recovery solutions have been developed. These mining operations may also enable the treatment of pollutant orphan sites to achieve compliance with recent regulations.

Also discover